Understanding Recycled Content in Modern Products

Recyclatanteil represents the percentage of recycled material contained within manufactured products, indicating environmental sustainability and resource efficiency. Furthermore, this measurement helps consumers and businesses understand how much virgin versus reclaimed material companies use. Growing environmental awareness drives demand for products incorporating recycled content rather than relying exclusively on new. Moreover, circular economy principles encourage maximizing material reuse reducing waste and environmental impact from resource extraction. Understanding recycled content percentages enables informed purchasing decisions supporting sustainability and responsible manufacturing practices today.

Definition and Measurement Standards

What Constitutes Recycled Content

Recycled content includes materials previously used in products that undergo processing for incorporation into new items. Additionally, pre-consumer recycled content comes from manufacturing scraps while post-consumer content derives from used products. Both types reduce virgin material demand though post-consumer recycling addresses waste streams more directly than. Consequently, distinguishing between pre-consumer and post-consumer content provides clearer picture of actual environmental benefits achieved. Certification programs establish standards ensuring accurate claims about recycled content percentages in commercial products sold.

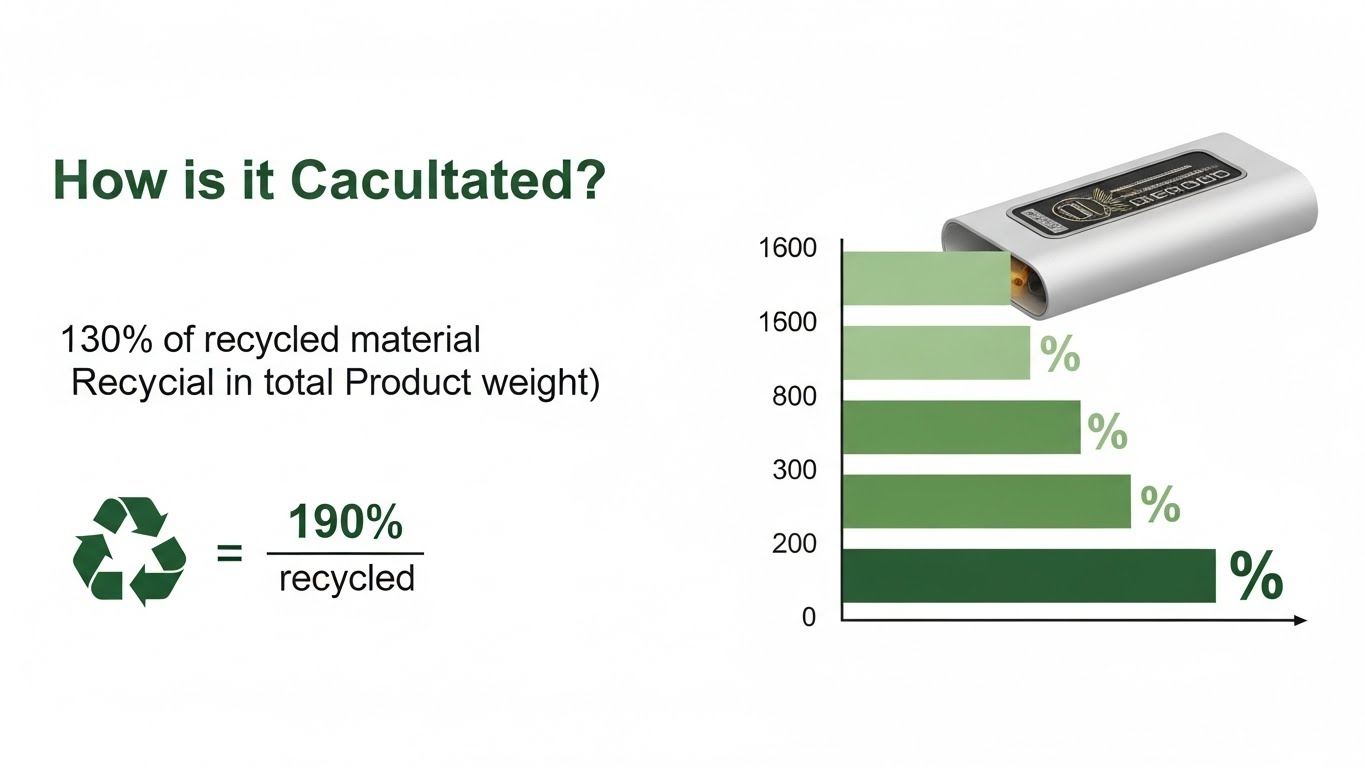

Calculation Methods

Manufacturers calculate recycled content by dividing recycled material weight by total product weight expressed as. Furthermore, some products contain recycled content in specific components rather than throughout entire product uniformly. Proper labeling specifies whether percentages apply to packaging, product itself, or both components combined together. Therefore, detailed specifications prevent misleading claims and help consumers understand exactly what percentages represent in. Standardized calculation methods enable fair comparisons between products and manufacturers competing in sustainable product markets.

Certification and Verification

Independent third-party certification verifies recycled content claims preventing greenwashing and ensuring accuracy of manufacturer statements. Moreover, certification programs like SCS Recycled Content or GreenCircle audit supply chains and testing processes. Verified claims carry more credibility with environmentally conscious consumers than unsubstantiated manufacturer assertions about sustainability. Consequently, certification investments signal genuine commitment to sustainability rather than superficial marketing claims without substance. Rigorous verification builds consumer trust and rewards manufacturers genuinely pursuing environmental responsibility through material choices.

Environmental Benefits

Reducing Virgin Resource Extraction

Using recycled materials decreases demand for virgin resources including timber, petroleum, and minerals requiring extraction. Additionally, resource extraction causes habitat destruction, water pollution, and ecosystem disruption that recycling helps minimize. Each ton of recycled material represents avoided environmental damage from mining, drilling, or harvesting operations. Therefore, increasing recycled content across product categories creates cumulative environmental benefits reducing extraction’s global footprint. Conservation of natural resources ensures availability for future generations while protecting ecosystems and biodiversity today.

Energy Savings in Manufacturing

Recycling typically requires significantly less energy than processing virgin materials into usable manufacturing feedstocks. Furthermore, aluminum recycling uses ninety-five percent less energy than producing aluminum from bauxite ore initially. Similar though smaller energy savings occur with paper, plastic, and glass recycling compared to virgin. Consequently, widespread recycling reduces manufacturing sector’s energy consumption and associated greenhouse gas emissions substantially overall. Energy efficiency improvements contribute to climate change mitigation while reducing operational costs for manufacturers implementing.

Waste Diversion from Landfills

Recycling diverts materials from landfills where they occupy space and potentially create environmental problems through leachate. Moreover, landfill capacity limitations make waste diversion increasingly important especially in densely populated regions facing. Materials recycling extends useful life preventing premature disposal and maximizing value extracted from resource investments. Therefore, recycling represents both waste management solution and resource conservation strategy addressing multiple environmental challenges simultaneously. Diversion reduces methane emissions from decomposing organic waste and prevents toxic substances from contaminating groundwater.

Common Materials and Applications

Plastics and Polymers

Recycled plastics find applications in packaging, construction materials, textiles, and durable goods across industries. Additionally, different plastic types require separate collection and processing streams complicating recycling logistics and economics. PET and HDPE represent most commonly recycled plastics with established markets and processing infrastructure worldwide. Consequently, recycled plastic content varies widely by application with some products achieving high percentages. Contamination and degradation limit how many times plastics undergo recycling before quality becomes unsuitable.

Paper and Cardboard

Paper products commonly contain high recycled content percentages with some reaching one hundred percent recycled. Furthermore, paper fibers degrade slightly with each recycling cycle limiting reprocessing to approximately five to seven. Virgin fiber additions maintain strength and quality in recycled paper products meeting performance standards required. Therefore, optimal recycled content balances environmental benefits with functional requirements for specific paper applications intended. Recycled paper manufacturing uses less water and energy compared to virgin pulp production from trees.

Metals and Alloys

Metals including aluminum, steel, and copper undergo recycling indefinitely without quality degradation unlike organic materials. Moreover, metal recycling provides excellent economics since recycled metal often costs less than virgin material. Construction, automotive, and packaging industries utilize significant recycled metal content in manufactured products routinely. Consequently, metal recycling represents mature industry with well-established collection, processing, and manufacturing integration worldwide comprehensively. Closed-loop systems recover metals from end-of-life products for reincorporation into new products continuously.

Glass and Ceramics

Glass recycling produces cullet that replaces raw materials in new glass manufacturing reducing energy requirements. Additionally, glass recycles indefinitely without quality loss though color sorting improves recycled glass marketability significantly. Recycled glass content varies by application with container glass often containing higher percentages than. Therefore, glass recycling provides environmental benefits though collection logistics and contamination present ongoing challenges regionally. Ceramic recycling remains less common due to technical challenges and limited markets for recycled material.

Manufacturing Integration

Supply Chain Considerations

Manufacturers sourcing recycled materials must ensure reliable supply chains providing consistent quality and adequate quantities. Furthermore, recycled material availability fluctuates based on collection rates, commodity prices, and market demand dynamics. Long-term supplier relationships and contracts help stabilize supply chains reducing disruption risks for manufacturers. Consequently, supply chain management becomes more complex when incorporating recycled content into production processes regularly. Strategic planning addresses potential shortages and quality variations maintaining production schedules despite supply uncertainties.

Quality Control Processes

Recycled materials require additional quality testing ensuring they meet specifications before incorporation into manufacturing processes. Moreover, contamination screening, composition analysis, and performance testing verify that recycled inputs match virgin material. Rigorous quality control prevents defects and maintains product performance standards that customers expect regardless of. Therefore, quality assurance investments ensure recycled content doesn’t compromise product functionality or durability over time. Advanced testing equipment and protocols enable manufacturers to confidently utilize recycled materials meeting exacting standards.

Processing Technologies

Specialized equipment and processes handle recycled materials accounting for composition variations and potential contaminants present. Additionally, innovations in sorting, cleaning, and reprocessing technologies continuously improve recycled material quality and usability. Mechanical, chemical, and advanced recycling methods each offer advantages for different material types and applications. Consequently, technology investments enable manufacturers to increase recycled content while maintaining product quality and performance. Processing advances expand which materials manufacturers can recycle and improve economics making recycling financially viable.

Consumer Considerations

Identifying Recycled Content

Product labels, certifications, and manufacturer disclosures help consumers identify products containing recycled materials and percentages. Furthermore, standardized symbols including the chasing arrows indicate recyclability but not necessarily recycled content itself. Consumers should seek specific recycled content claims rather than assuming recyclable products contain recycled materials. Therefore, informed purchasing requires understanding labeling conventions and looking beyond vague environmental claims without specifics. Third-party certifications provide most reliable verification of recycled content claims on consumer products sold.

Performance and Quality Perceptions

Historically, recycled products sometimes suffered quality perceptions despite often matching virgin material performance in testing. Moreover, modern recycling technologies produce materials meeting or exceeding virgin material specifications in many applications. Consumer education helps overcome outdated perceptions that recycled necessarily means inferior quality or reduced performance. Consequently, manufacturers must demonstrate through testing and warranties that recycled content doesn’t compromise product value. Quality assurance and transparent communication build consumer confidence in products containing recycled materials increasingly today.

Price Considerations

Recycled content products sometimes cost more due to collection, processing, and certification expenses exceeding virgin. Additionally, market dynamics including commodity prices affect whether recycled materials cost more or less than. Environmental benefits justify modest price premiums for consumers prioritizing sustainability over lowest possible cost. Therefore, pricing strategies must balance production costs with consumer willingness to pay for environmental attributes. Growing scale and efficiency improvements gradually reduce cost premiums making recycled products increasingly price-competitive.

Regulatory Landscape

Mandatory Content Requirements

Some jurisdictions implement minimum recycled content requirements for specific product categories including packaging and construction. Furthermore, extended producer responsibility legislation often includes recycled content targets alongside recyclability and collection requirements. Mandatory standards ensure baseline environmental performance rather than relying solely on voluntary manufacturer initiatives alone. Consequently, regulations drive industry-wide improvements that voluntary programs might not achieve at comparable scale or. Compliance requirements create level playing fields preventing competitors from gaining advantages through lower environmental standards.

Incentive Programs

Government incentives including tax credits, grants, and preferential procurement support manufacturers using recycled materials. Moreover, incentives help offset higher costs associated with recycled content making it economically attractive for. Public procurement preferences favor products meeting recycled content thresholds encouraging manufacturers to meet specifications qualifying. Therefore, policy tools beyond mandates help create markets and economic conditions supporting recycled material utilization. Incentive programs accelerate transitions toward circular economy models complementing regulatory requirements with economic encouragement.

Labeling and Disclosure Rules

Regulations govern how manufacturers communicate recycled content preventing misleading claims and ensuring consumer protection from. Additionally, standardized labeling requirements enable consumers to compare products and make informed purchasing decisions based. Disclosure rules prevent greenwashing where companies exaggerate environmental benefits through vague or unsubstantiated sustainability claims. Consequently, clear labeling standards build consumer trust and reward manufacturers making genuine environmental improvements verifiably. Enforcement ensures compliance and penalizes false claims protecting both consumers and honest manufacturers from.

Challenges and Limitations

Collection Infrastructure Gaps

Inadequate collection infrastructure in many regions limits recycled material availability constraining manufacturer ability to source. Furthermore, contamination from improper sorting reduces material quality and increases processing costs undermining recycling economics significantly. Investment in collection systems and consumer education improves material quality and quantity available for manufacturing. Therefore, infrastructure development represents critical enabler for increasing recycled content across product categories and industries. Public-private partnerships can accelerate infrastructure expansion addressing collection gaps limiting recycling potential currently today.

Economic Viability Concerns

Fluctuating commodity prices create economic uncertainty for recycling operations dependent on selling recovered materials profitably. Moreover, virgin material prices sometimes drop below recycled material costs eliminating economic incentives for purchasing. Policies including virgin material taxes or recycled content mandates help stabilize markets ensuring recycling remains viable. Consequently, economic challenges require policy interventions creating favorable conditions for recycled material markets to flourish. Long-term contracts and diversified revenue streams help recyclers weather commodity price volatility and uncertainty.

Technical Performance Limitations

Some applications require virgin materials due to performance requirements that current recycled materials cannot meet. Additionally, aerospace, medical devices, and food packaging often restrict recycled content due to safety or regulatory. Ongoing research develops recycling technologies producing materials meeting stringent specifications for demanding applications increasingly today. Therefore, technical limitations represent temporary rather than permanent barriers as recycling science and technology advance. Innovation continually expands applications where recycled materials perform adequately replacing virgin materials in more product.

Future Trends and Innovations

Advanced Recycling Technologies

Chemical recycling breaks materials down to molecular level creating virgin-quality feedstocks from complex waste streams. Furthermore, artificial intelligence and robotics improve sorting accuracy and efficiency increasing recovered material quality and. Innovations enable recycling of previously unrecyclable materials expanding circular economy potential across more product categories. Consequently, technology development addresses current limitations making higher recycled content feasible in more applications going. Investment in recycling innovation accelerates transition toward truly circular economy minimizing waste and virgin resource.

Circular Economy Integration

Circular economy thinking designs products for recyclability from inception rather than addressing end-of-life as afterthought. Moreover, product-as-service models maintain manufacturer ownership incentivizing durable design and material recovery at end-of-life. Closed-loop systems where manufacturers reclaim their own products ensure high-quality material recovery for remanufacturing cycles. Therefore, systemic changes beyond individual recycled content percentages transform how society produces and consumes goods. Circular approaches maximize resource value and minimize waste through integrated design, production, and recovery systems.

Consumer Demand Growth

Increasing environmental awareness drives consumer demand for sustainable products containing recycled content and minimal packaging. Additionally, younger generations particularly prioritize environmental attributes when making purchasing decisions influencing market trends significantly. Brand reputation increasingly depends on demonstrable sustainability commitments including measurable recycled content increases over time. Consequently, market forces complement regulatory requirements motivating manufacturers to increase recycled content voluntarily proactively today. Consumer preferences create business cases for sustainability investments beyond mere regulatory compliance requirements alone.

Conclusion

Recycled content percentages represent important sustainability metric indicating how effectively manufacturers utilize recovered materials versus virgin. Understanding recycled content helps consumers, businesses, and policymakers make informed decisions supporting circular economy transitions globally. Furthermore, increasing recycled content across product categories delivers environmental benefits including resource conservation and waste reduction. Challenges including infrastructure gaps and economic volatility require ongoing attention through policy, investment, and innovation. Continued progress toward higher recycled content percentages represents essential component of sustainable development and environmental responsibility. Collective efforts from manufacturers, consumers, and governments can accelerate transitions toward truly circular material economies worldwide.